Introduction

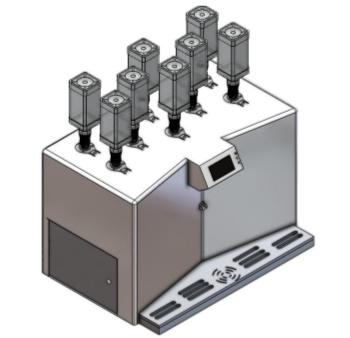

The Automatic Cocktail Maker is a full-stack mechatronics project completed as part of a Faculty of Technology & Bionics group project. Our goal was simple to state but demanding to execute: create a compact machine that produces bar-quality, layered cocktails at the push of a button while meeting real-world constraints of hygiene, serviceability, and repeatable taste. The system supports eight bottles, dispenses precise 2 cl shots, and guides the entire process through a touchscreen interface, so a user can pick a recipe and watch it assemble cleanly in the glass.

From day one we treated it like a product, not just a prototype. That meant designing for modularity (detachable panels, service doors, removable grill), cleanability (common tank with internal 360° spray and controlled flush), and clear user feedback (status LEDs and UI states). Mechanically, the focus was a rigid, easy-to-manufacture frame with straightforward access to the dosing hardware; electronically, a microcontroller-driven stack coordinated servo-actuated dosing and a solenoid-based cleaning cycle; and at the system level, we prioritized reliable portioning, minimal cross-contamination, and smooth flow for attractive visual layering.

My role centered on mechanical design and CAD, assembly drawings, and production planning & make-vs-buy inputs—ensuring that what we modeled could actually be built, serviced, and iterated. The result is a platform that balances precision (consistent 2 cl shots), user experience (touch UI, clear signals), and maintenance practicality (fast teardown and cleaning)—a small but complete example of turning a concept into a consumer-grade mechatronic appliance.